Product

Content

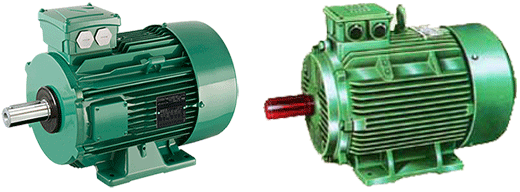

We are manufacturing & supplying electric motors ranging from 0.18 KW to 50 KW0.

We are giving detailed specification of motors as under.

All our Motors are developed to confirm the latest Indian Standards. Specifications as well as the International Standards for their performance and dimensions too. This helps in making the size of the products most compact and elegant, and offers the very important interchangability.

Our Motors are being produced in modern and well equipped factory adopting latest techniques in designing and developing the motors, rigid quality control at almost all stages of production and latest testing fascilities as per various National & International standards & have helped in raising the image of our Motors as a quality product making them acceptable to the various prestigious applications throughout the country.

Our Electric motors finds applications in various Industries like : Plastic, Rubber, Textile, Machine Tools, Paper, Printing, Wire drawing, Cables Pharmaceutical Leather, Rolling Mill, Synthetic Yarn etc.

1) Standard 3 Phase Squirrel Cage Induction Motors 0.093 KW to 50 KW in all speeds with all types of construction.

2) Flanged Motors from 0.09 KW to 50 KW either for horizontal or vertical operations.

3) Textile Motors - Surface Cooled Loom Motors cradle/foot mounted 0.55 KW to 1.1 K and 1000 RPM or 750 RPM. Card Motors 1.1KW to 2.2 KW High Torque .Ring frame motors 5.5 KW to 15 KW.

4) Standard Single Phase Motors from 0.093 KW to 1.5 KW in 1500 & 3000 RPM.

STANDARDS ADOPTED

Dimensionally : IEC Recommendations 72-1 and 72-2, IS:1231 and IS : 2223

Electrical Specification : IS:325 / 1978 & IEC:34

Terminal Box : The protection provided in the Standard Motors is IP:44 & IP-55 As Per ref:IS:4691.

The Standard designs are For class of insulation : ‘B’ & ‘F’ Class,insulatio

ELECTRIC FEATURES

Supply & Voltage : 415 Volt for 3 Phase and 220/230V

Frequency : 50 Hzs

Voltage Regulation : + 6%

Fluctuation Frequency Fluctuation : + 6%

Each rotor of the motor is dynamically balanced with the full key. The amplitude of Vibration for Standard Motors will be within the limits as specified in IS:4729. Special low vibration Motors for special applications to machine tools and others can be dealt with.

The bearing seats and the shaft are grounded as per IS tolerances and stampings are press fitted to remove the possible magnetic noises.